Manual Band Saws Harbor Freight

Manual Band Saw Rental Home Depot

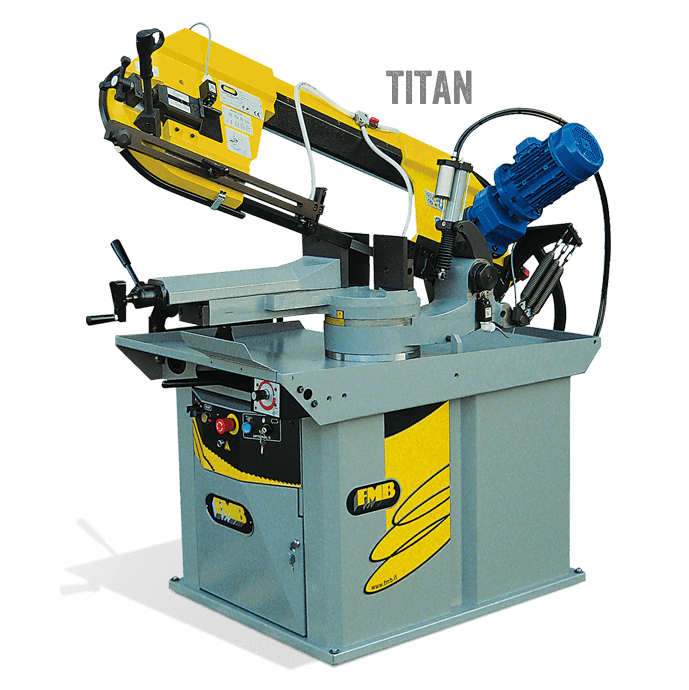

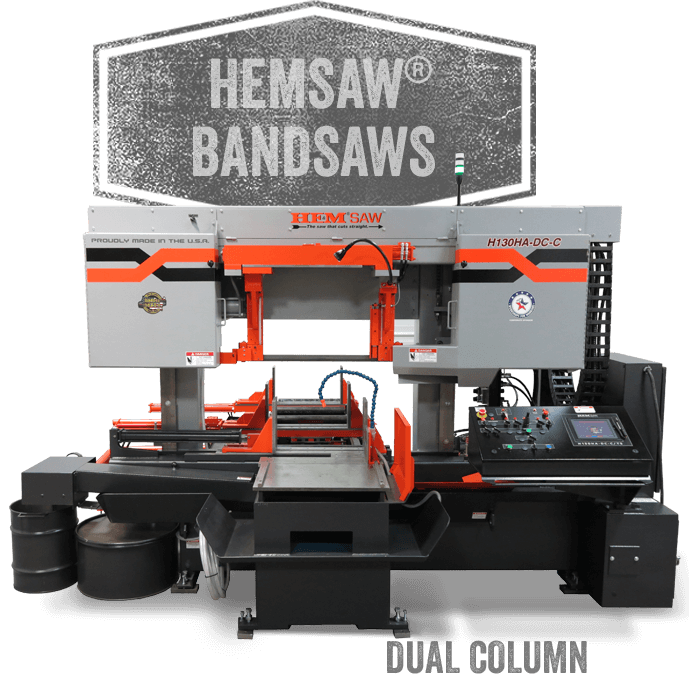

A band saw has the main advantage of being able do a uniform cut. This is possible because of the uniform tooth load.

Band saws can be used to work with wood in a variety of ways. The more you use them, the better your craft will be.